Search

Timken India to start making CRBs, SRBs locally at Bharuch

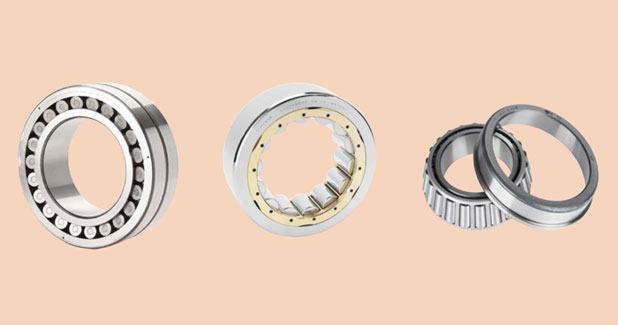

Timken India plans to set up a new facility at Bharuch in Gujarat to manufacture spherical roller bearings (SRBs) cylindrical roller bearings (CRBs) and other components.

Timken India to start making CRBs, SRBs locally at Bharuch

Timken India plans to set up a new facility at Bharuch in Gujarat to manufacture spherical roller bearings (SRBs) cylindrical roller bearings (CRBs) and other components.

Demand in 2021 will be better than this year

Timken has been manufacturing in India for the last 30 years. Sanjay Koul, Managing Director, Timken India, explains the current market scenario and the company’s products and solutions for the CE market.

BEARING IT ALL!

Unlike passenger vehicles, when it comes to construction equipment applications bearings should be compatible with loads and harsh working conditions. Construction and mining are mostly encountered with dust, mud, and huge loads. Bearings for construction and mining applications must be rugged enough to bear these extreme conditions. For such conditions, the various ranges of bearings like cylindrical roller bearings, spherical roller bearings, tapered roller bearings, plain bearings and slew ring bearings are used as per the application within the equipment. Such bearings will provide longer life and higher efficiency to the equipment and machinery. With customers now looking for more than just a bearing supplier, most of the bearing manufacturers are looking forward to improving the product features to live up to the expectation from customers. In any industry segment, be it is automobile, power, or industrial machinery, the concept of lightweighting is fast gaining momentum as it leads to fuel saving, resulting in overall economy. Customers would need more reliable systems as they are not only looking at bearings, but also sub-assembly systems such as housings, lubricants, and additional components like seals. Different equipment will require different application requirements. Considering this, bearings manufacturers are also focusing on customising their products. The Special Focus section elaborates more on the bearings for CE applications. Automation plays a major role in the productivity and efficiency of a system or process. Painting is a major part of construction equipment manufacturing process. One of the significant areas to maximise availability in construction equipment manufacturing plant is the paint shop. Paint provides aesthetic value and boosts physical properties of equipment. It offers durability, resistance against corrosion, adds mechanical protection, and guards against weather conditions, since equipment are typically deployed in all terrains and conditions. Edge Controller from B&R helps to monitor paint shops, increase efficiency and provides transparency. The Technology elaborates on the automation solution in paint shop. Another Technology highlighted is that Siemens and IBM announced the availability of a new solution designed to optimise the Service Lifecycle Management of assets. The new solution establishes an end-to-end digital thread between equipment manufacturers and the owner/operators of that equipment.

Rolling innovations

Bearings for construction and mining applications have seen innovative developments in the recent times. With the construction and mining equipment market is growing, the momentum of innovation in bearings is to pick up in the coming days.

Facilitating efficiency

Bearings fulfill a number of important functions, starting with their ability to reduce friction. Other primary functions include supporting a load, promoting the efficient transmission of power and ensuring alignment is maintained.

Rolling On Smoothly

Bearings are an integral part of equipment which increase efficiency by reducing friction, while maintaining the operational requirements. In this fast moving age of industrialisation, efficiency is the key to success. Construction equipment operates in very demanding environments

Orbit Bearings onto a New Growth Phase

Orbit will be opening its new factory early next year as a part of its ambitious growth strategy. The bearings segment in India has come a long way in the last decade showing rapid growth

Bearings for Smooth and Durable Functioning

Not as interesting or inspiring as a tiny transistor in an electronic circuit, a bearing is as important as a transistor when it comes to the smooth functioning of a machine.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com